Logical

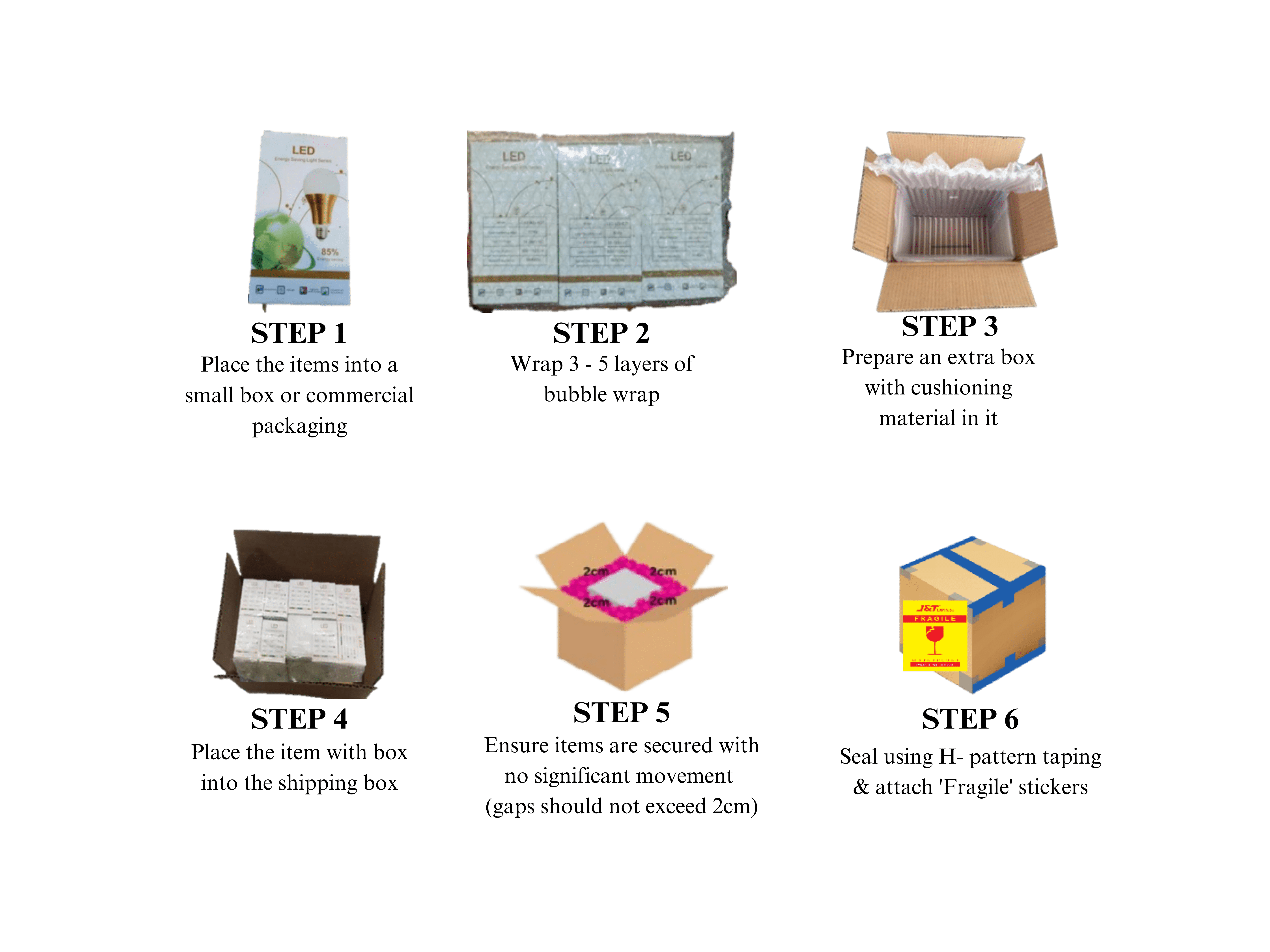

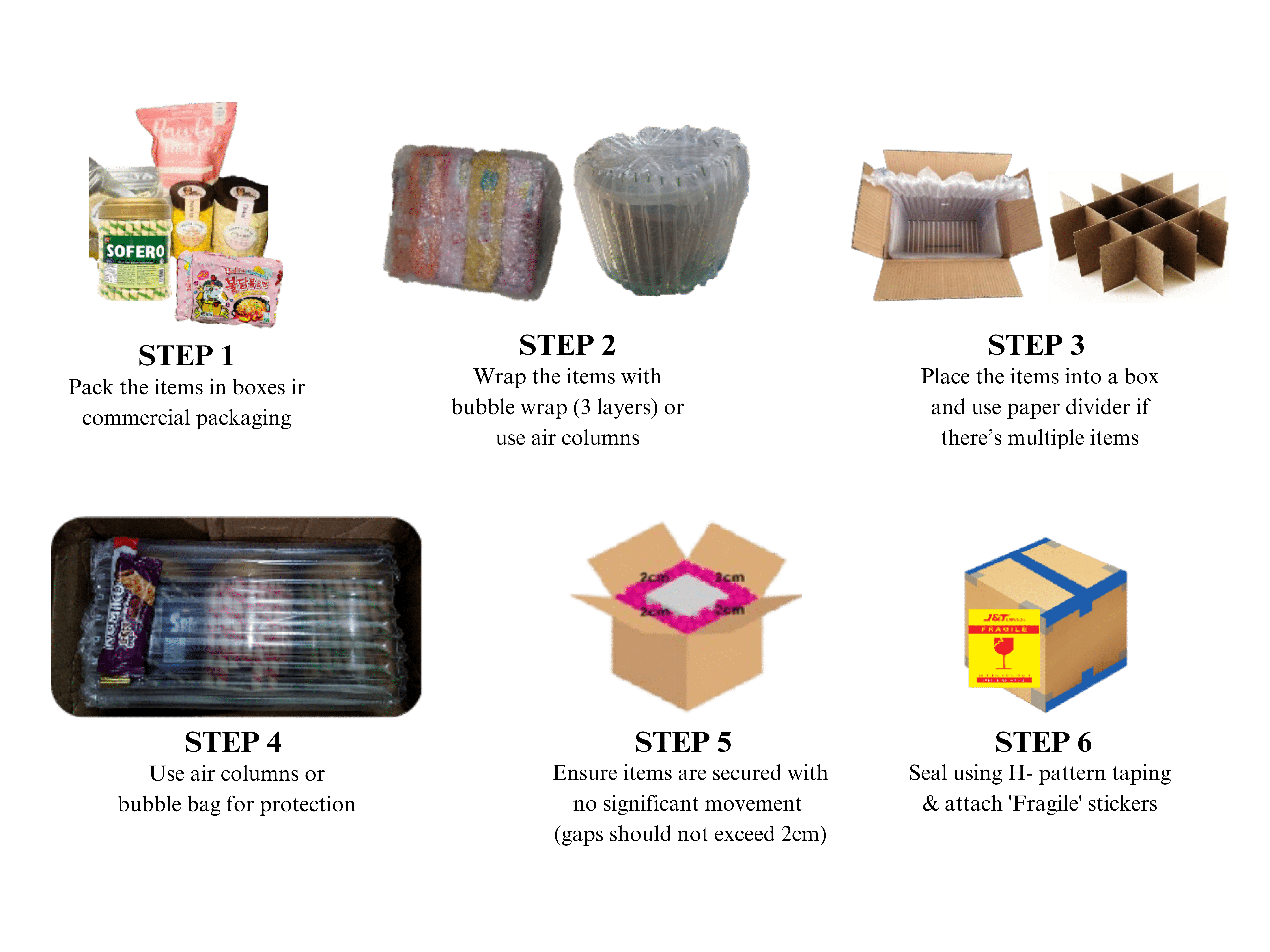

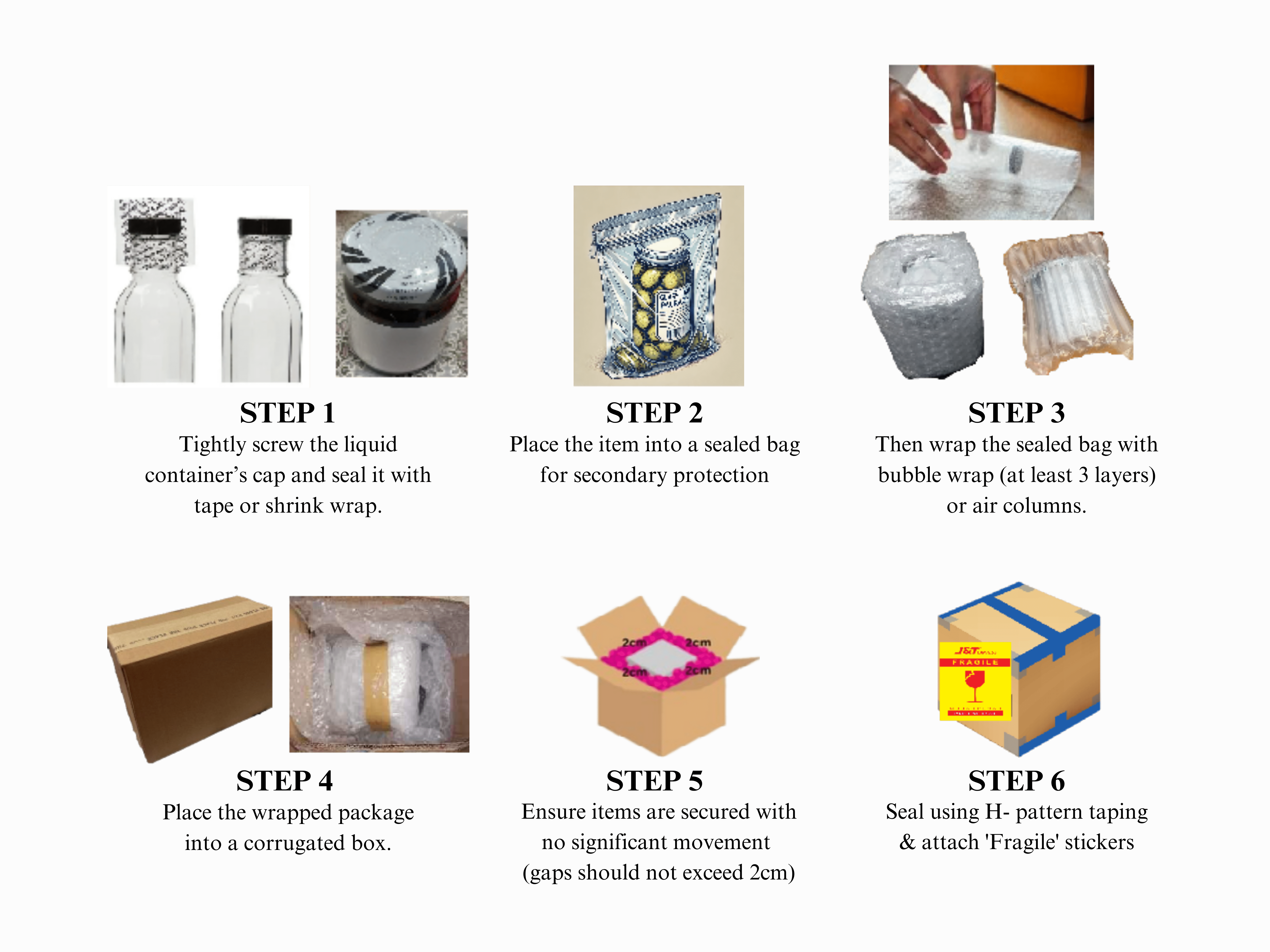

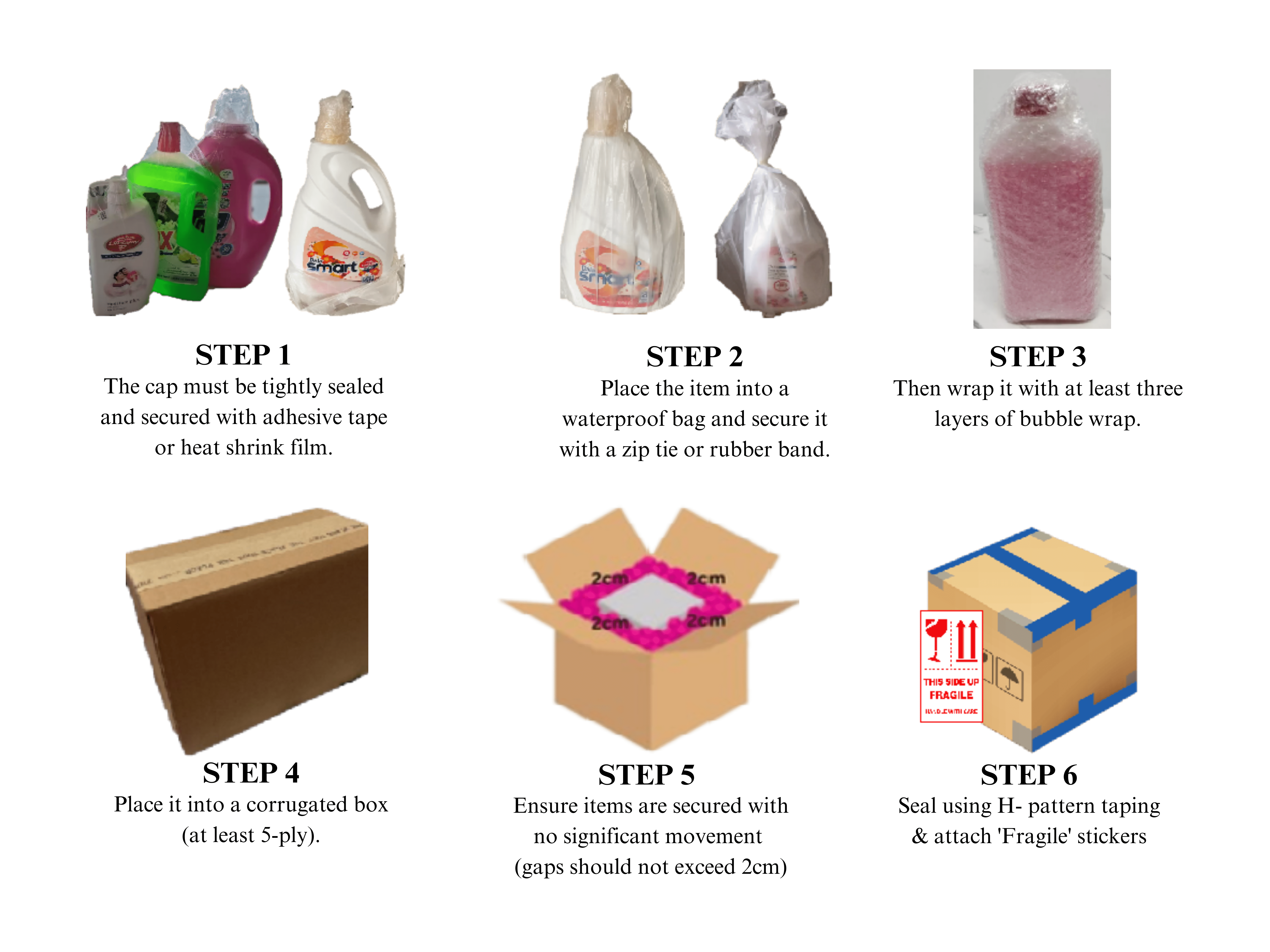

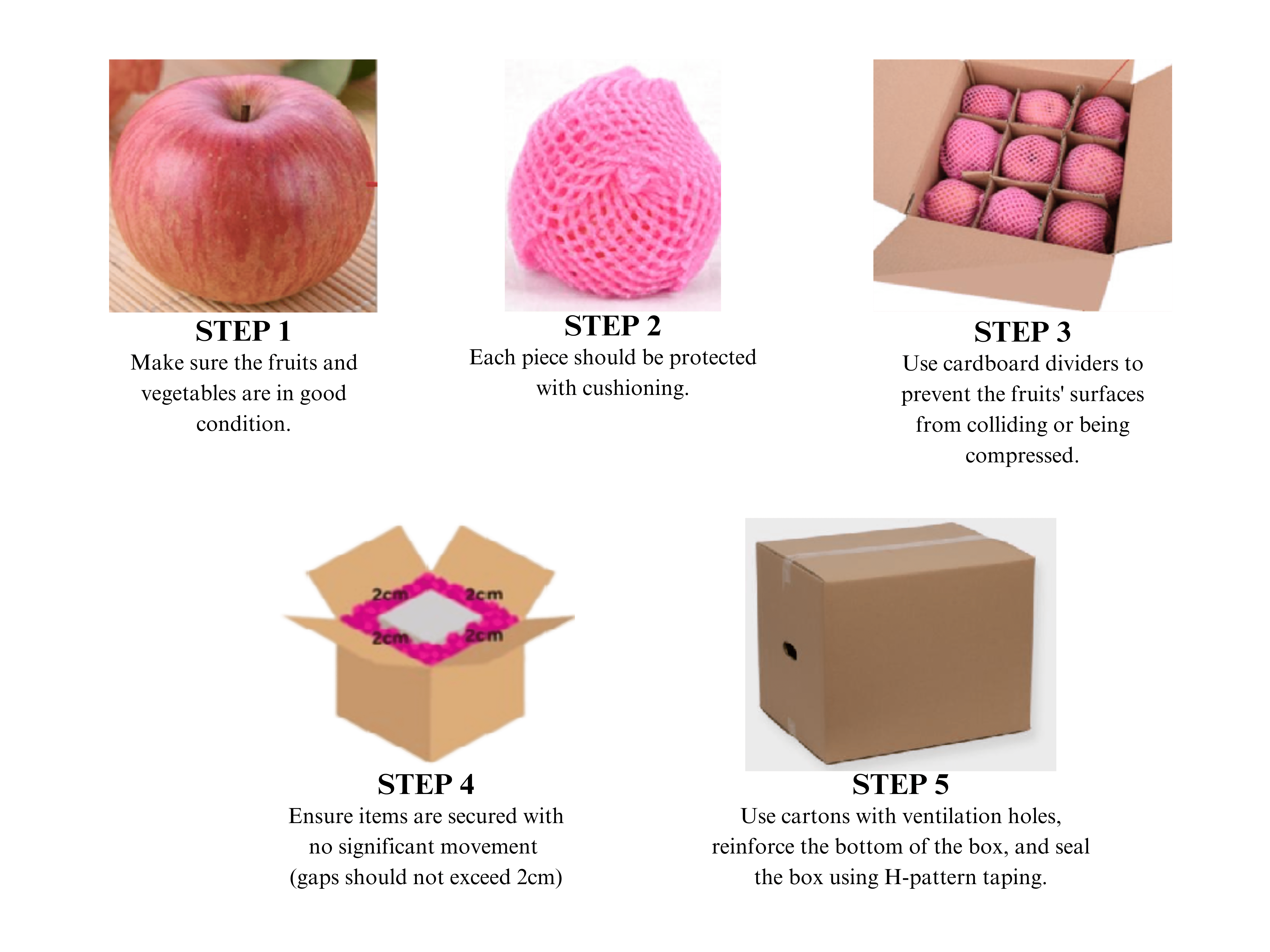

To ensure safe and efficient packaging, it is crucial to use appropriately sized packaging materials to prevent items from moving or colliding during transit, minimizing damage and waste. Overfilled packaging can exert excessive internal pressure, deforming the box and damaging items, while underfilled packaging creates gaps that lead to uneven stress, causing box collapse, dents, or tilting, which affects customer satisfaction. Suitable filling materials such as bubble wrap, PE foam, or newspapers should be used to fill empty spaces within the box . Packaging must also be sturdy enough to withstand the item's weight, especially for irregular or round shapes. Polystyrene boxes require additional external protection due to their fragility. Plastic bags are unsuitable as outer packaging, and appropriate boxes or shipping bags should be used instead. When shipping items in their manufacturer’s original packaging, which often includes protective fillers and tamper-evident seals, minimal extra fillers should be added. If the original packaging is non-corrugated , it must be placed inside a corrugated box with bubble wrap and fillers to prevent movement, whereas corrugated original packaging should be wrapped with ample cushioning materials and concealed with black shrink wrap to reduce theft or tampering risks. Additionally, all liquid containers , even if sturdy, must be placed inside waterproof bags to prevent leakage and contamination of other parcels.

Safety

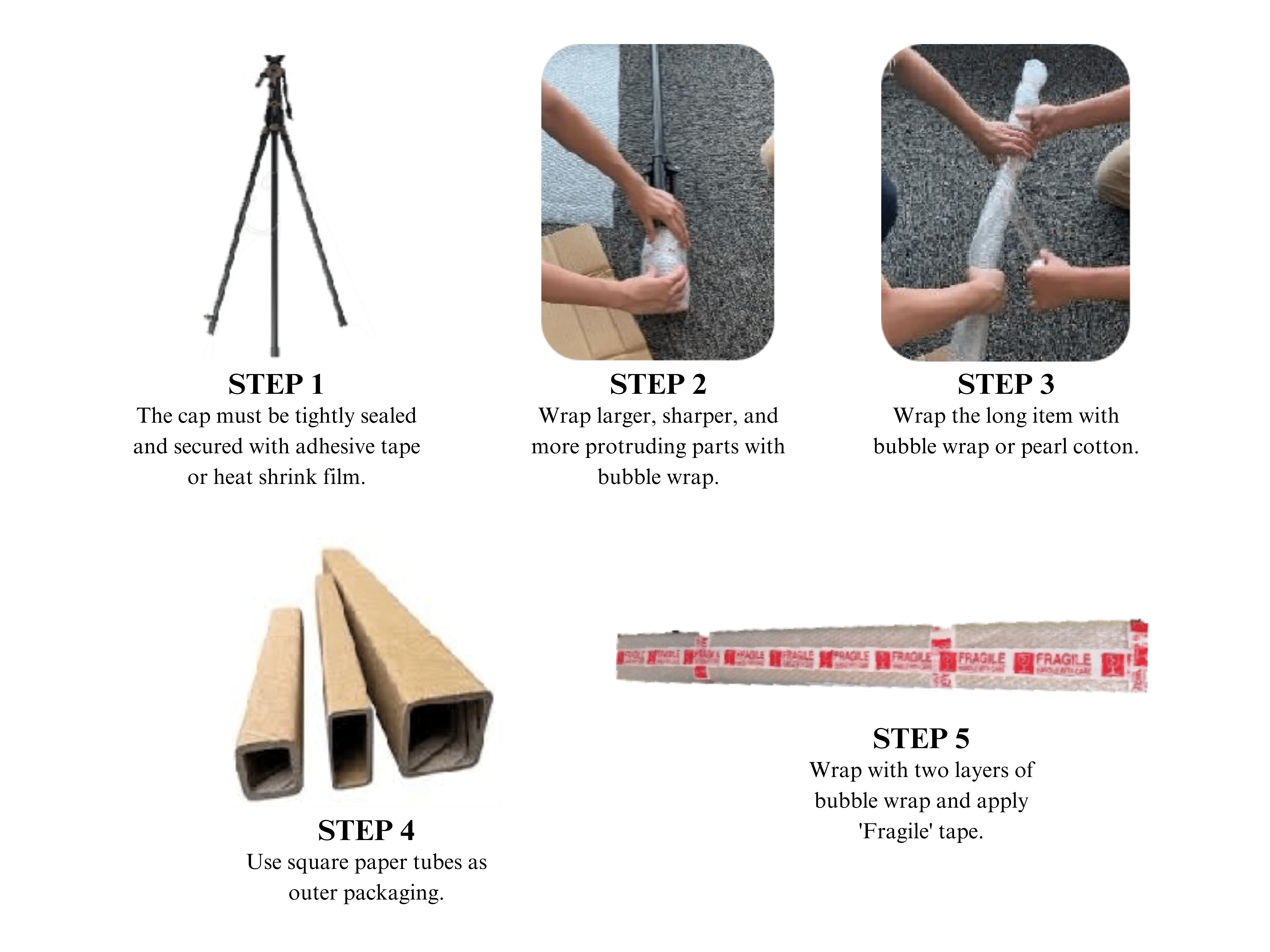

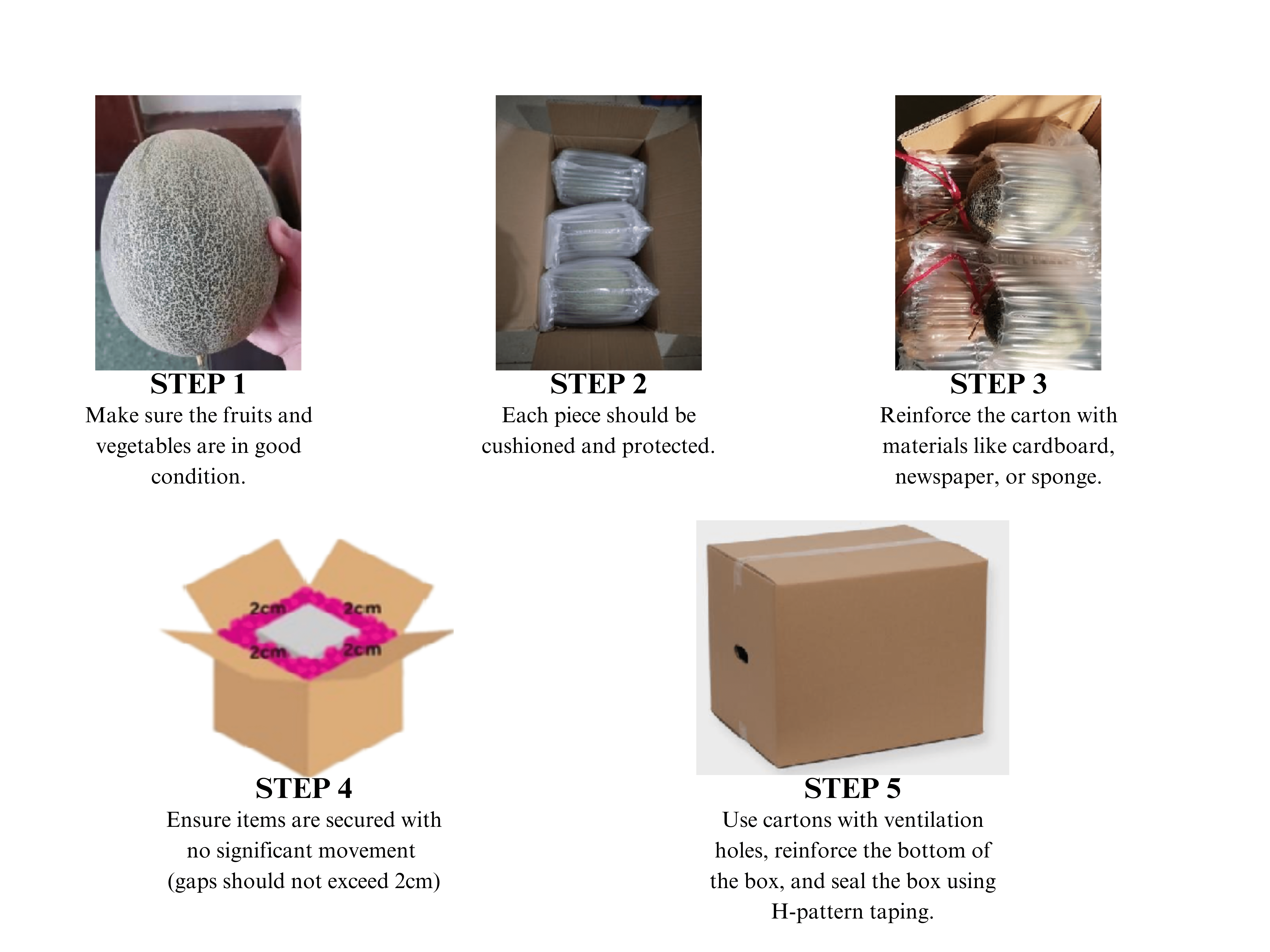

Safety is a critical aspect of logistics packaging, ensuring that parcels are securely delivered, capable of absorbing impacts, resistant to theft, and do not endanger personnel or other shipments. Using durable packaging materials, such as reinforced cartons or waterproof materials with sufficient thickness and impact resistance, helps withstand external pressure and vibrations. Fragile or pressure-sensitive items require internal reinforcement, such as partitions or protective layers, to separate them from external forces and prevent damage. Filling empty spaces within boxes with foam, bubble wrap, or similar materials prevents item movement during transit, with gaps not exceeding 2 cm. Shaking the package can help ensure items remain securely in place. Sharp objects must not protrude from the packaging, as they can damage the box, harm other parcels, or pose risks to staff; wrapping them in foam or cardboard prevents direct contact with the outer layer. For valuable items, using dark or black tape and shipping bags helps conceal the contents, while fragile stickers provide handling instructions. Lastly, it is essential to ensure that no prohibited or dangerous goods are included in the shipment. A detailed list of restricted items can be found on the official J&T Express Malaysia website: https://jtexpress.my/prohibited/domestic.

Reuse / Recycle

Recycling materials for packaging helps reduce waste while maintaining secure transit. Unused boxes can be repurposed for packing, and PE foam or bubble wrap in usable condition can be used for inner filling. To prevent confusion during shipping, all old labels, including previous addresses, dangerous goods indicators, and stickers, should be removed from recycled boxes. When using recycled or reused materials, it is important to follow key precautions:

- Fill the empty spaces within the box.

- One waybill with multiple parcels in different shapes and sizes in prohibited, as it is very theft-prone and damage-prone during the transit process.

- Do not overload the box.

- Do not use bags made of fabric or cloth to pack the parcel.

- Do not pack the parcel with damaged boxes.

- Make sure the previous leftover material is in clean, dry, sturdy, and usable condition.

- Newspapers, eggshells, and other fillers can be used as filling materials for saving material cost purposes.

Outer Packaging Materials

A4 Envelope

A2, A3, A4 Courier Flyer

Next Day Delivery (NDD) (A2, A3 & A4)

XS, S, M, L Boxes

Corrugated Box

Honeycomb Box

Wooden Box

Corrugated cardboard box with holes

Stretch Film

Waterproof Woven Bag

Inner Packaging Materials

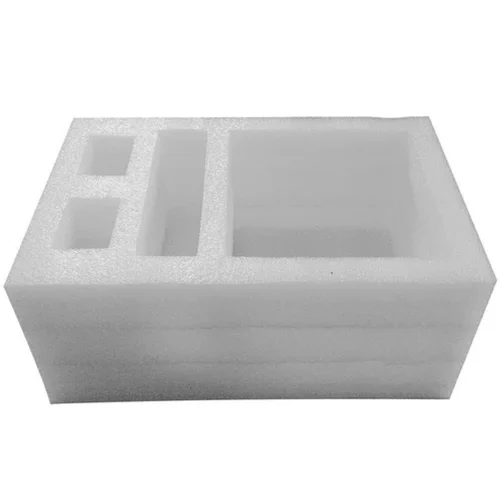

Pearl Cotton (EPE Foam)

Bubble Wrap

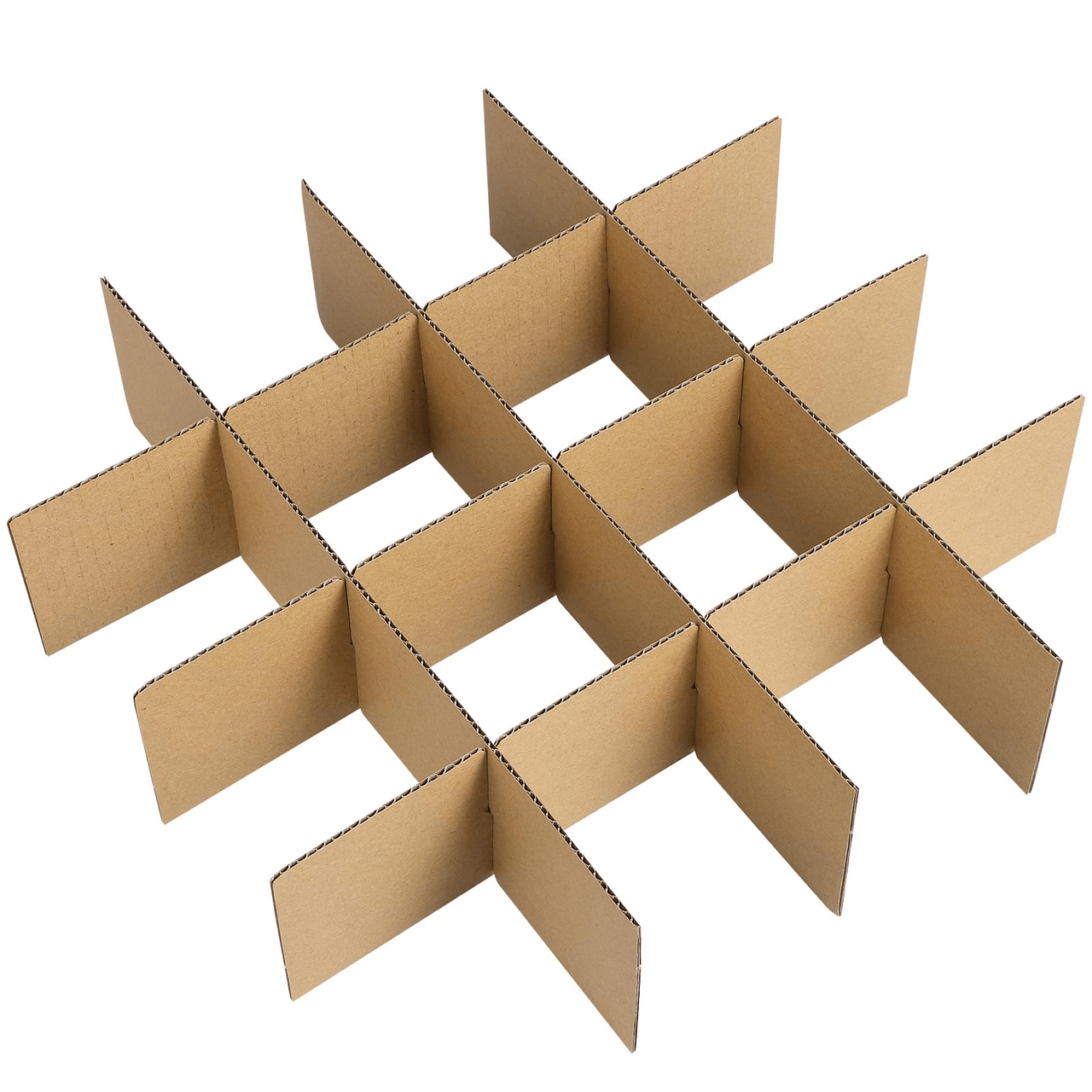

Cardboard Divider (Cross - Shaped or Grid - Shaped)

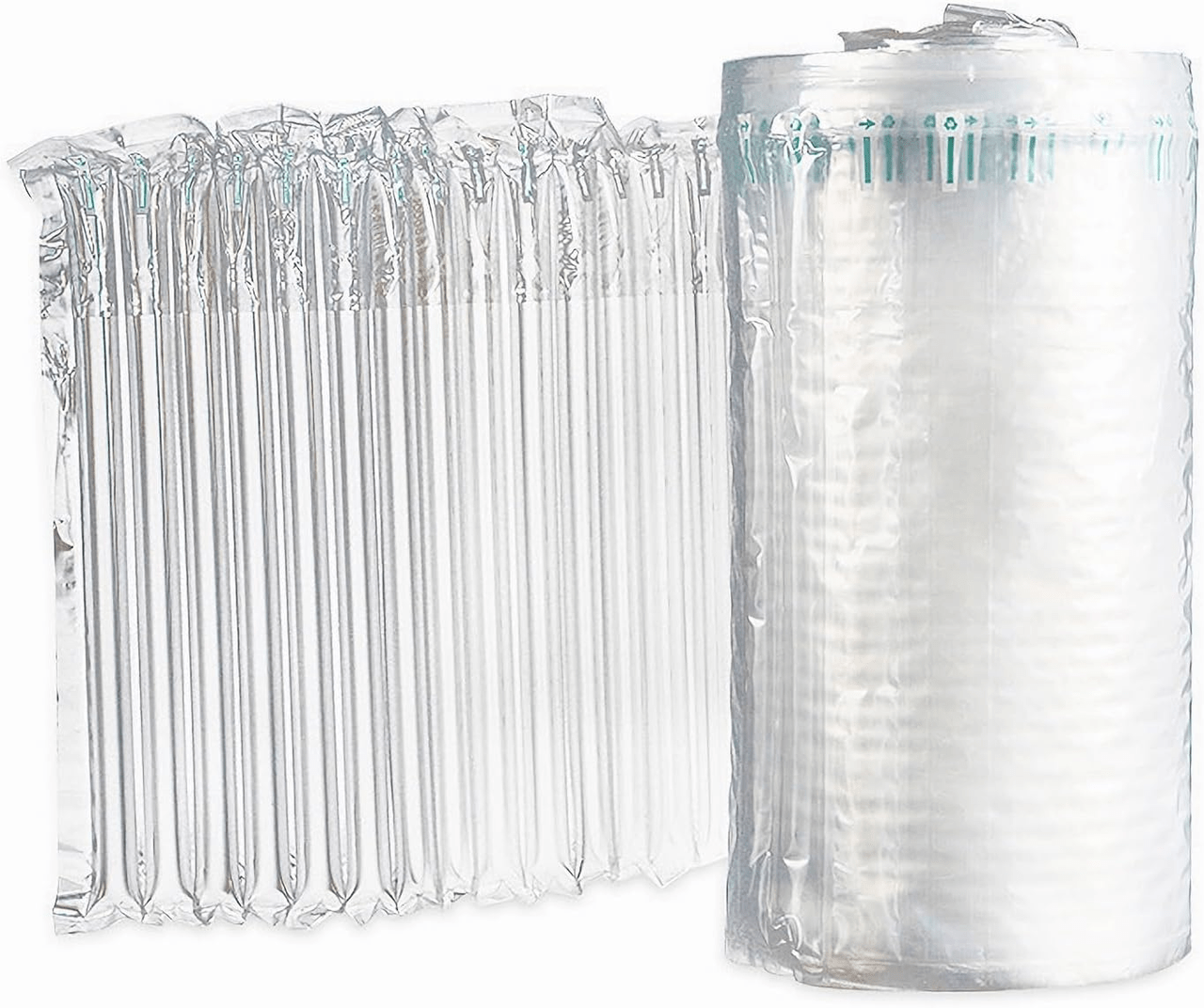

Air Column Bag

Inflatable air bags

Sealing bags

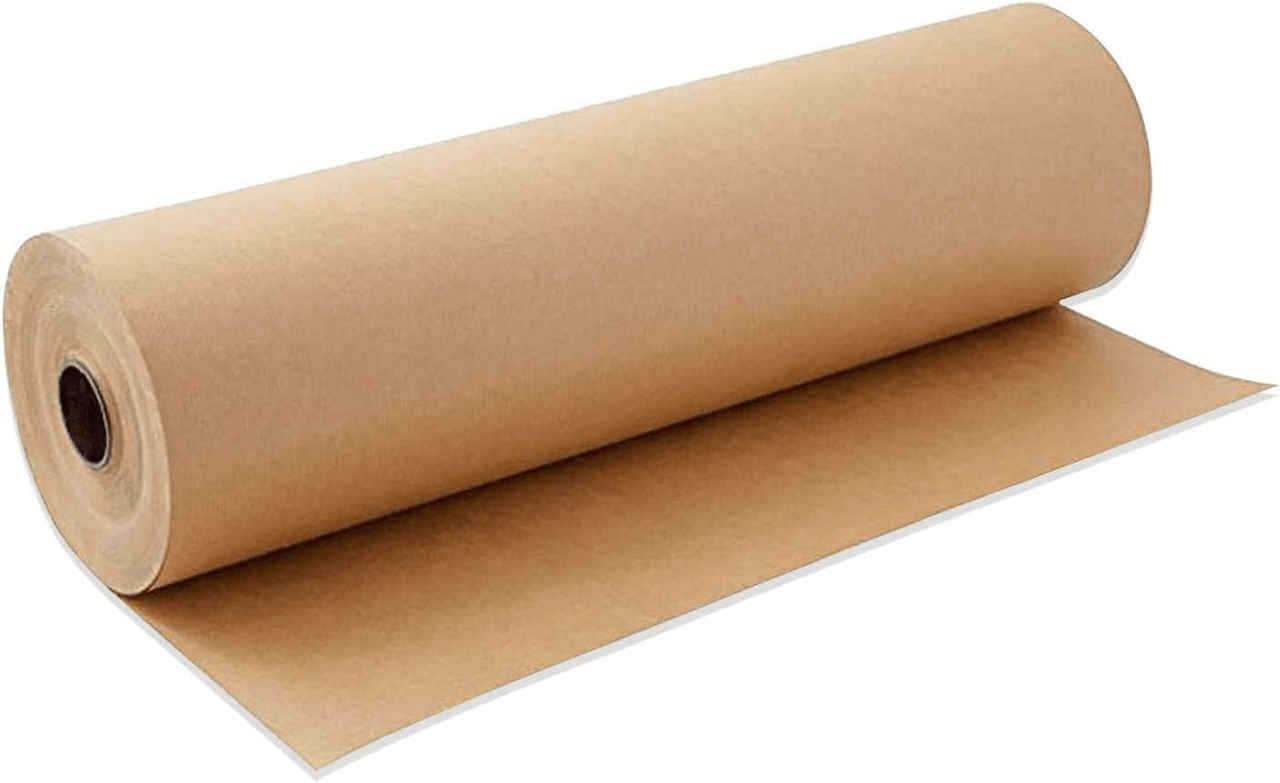

Recycled Kraft Paper

Waterproof Plastic Bags

Foam Boxes

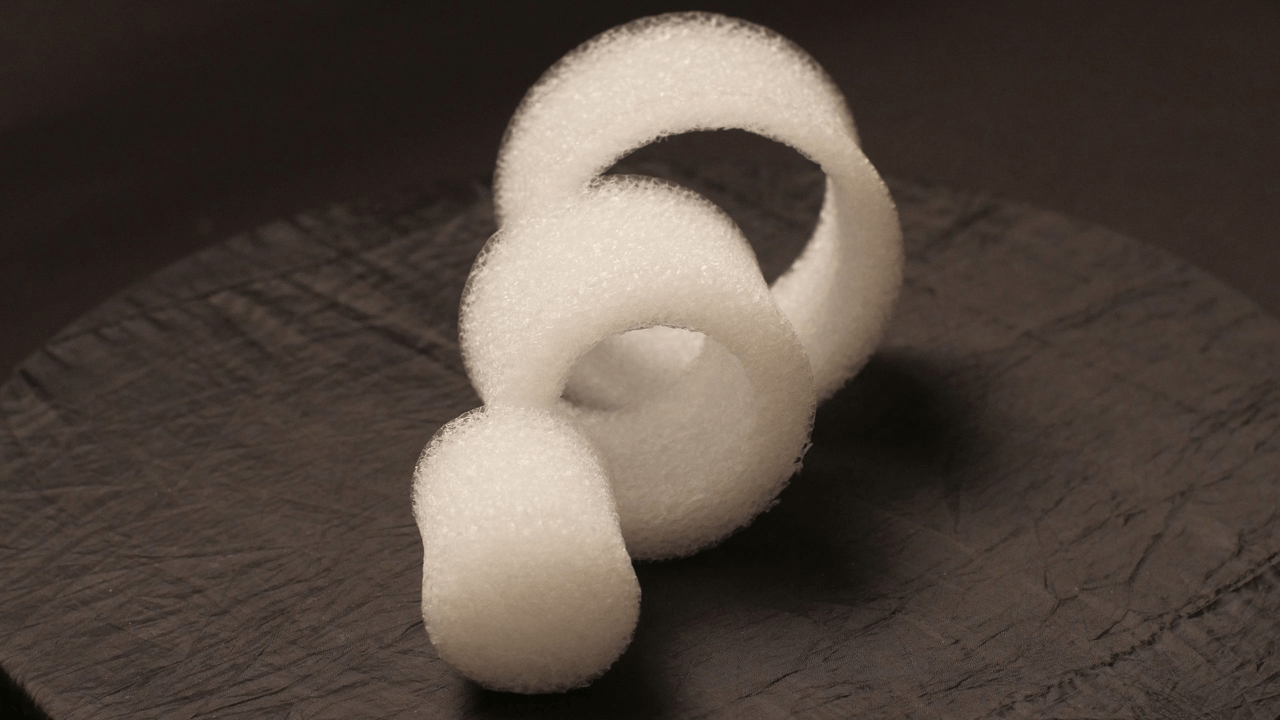

Pearl Cotton Blocks/Packing Peanuts

EPE Protective Cover

Honeycomb Paper

Foam Net

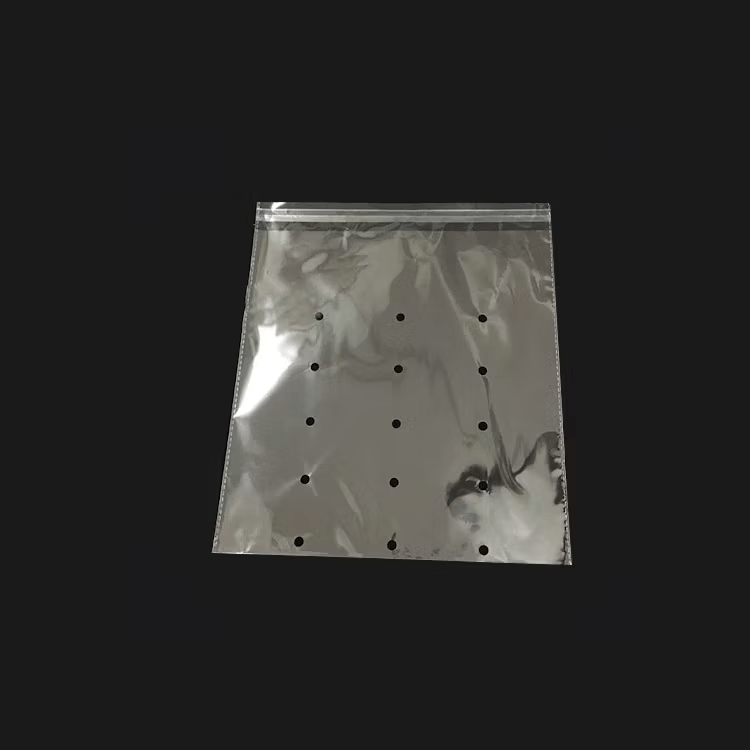

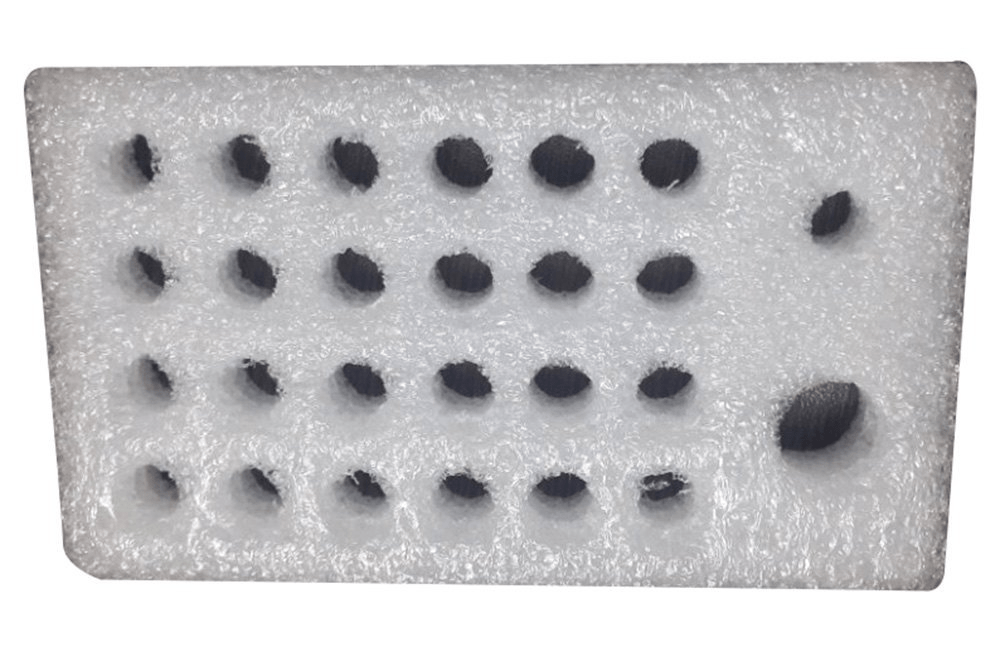

Perforated Plastic Bag

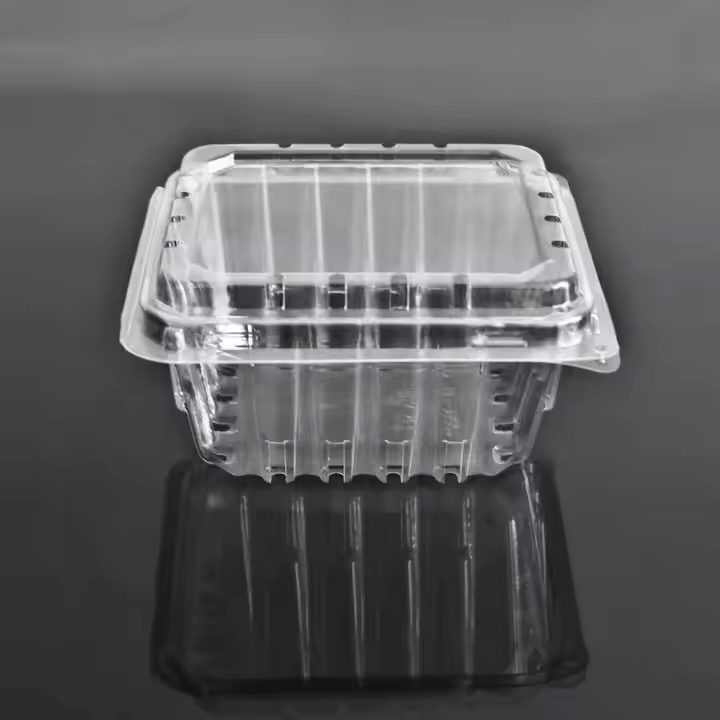

Perforated Freshness Box

Plastic Tray / PE Foam Tray / APET Tray

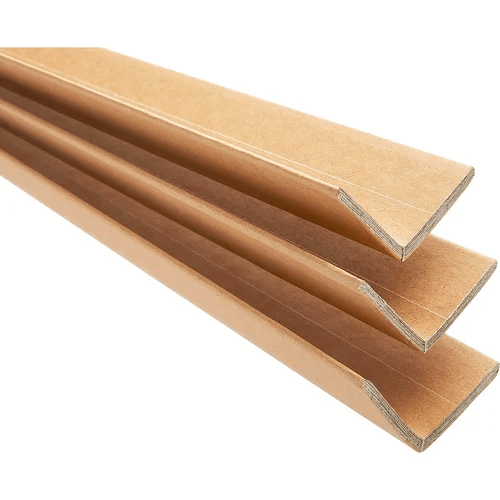

Paper Edge Protector

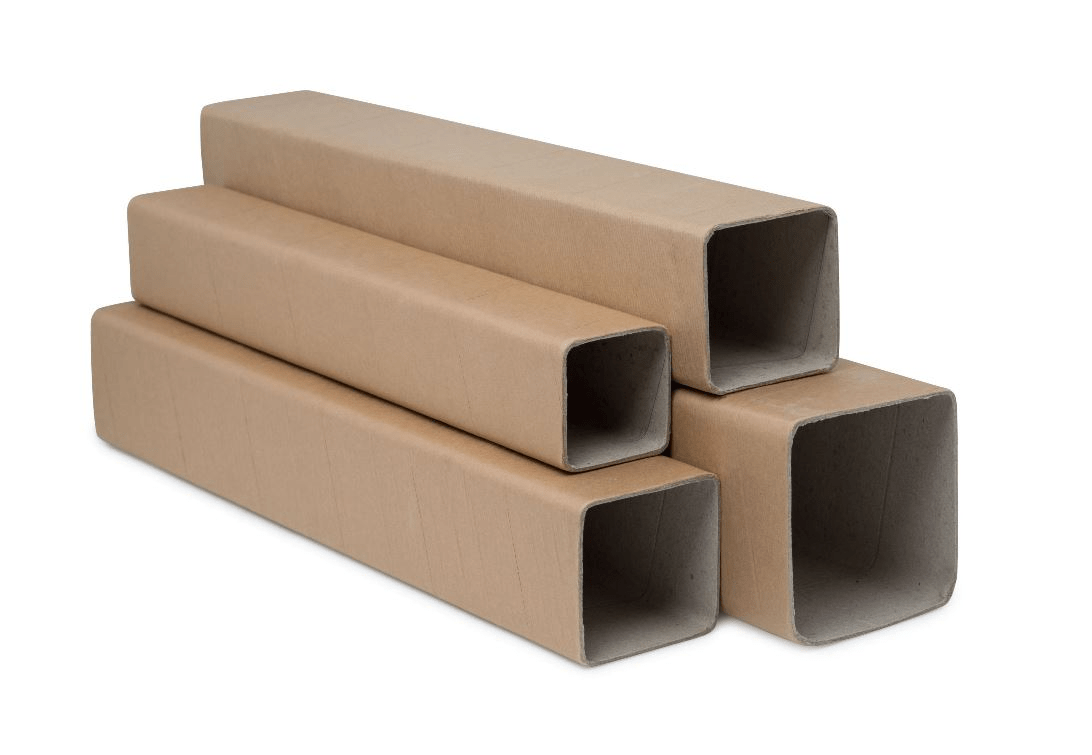

Square Paper Tubes

Gridded EPE Foam

Shredded Paper/Newspaper

Type Of Packaging

Types Of Item

Drop Test Procedure

Standard Drop Test: Drop test should preferably be done for all parcels to check for the effectiveness of the packaging to minimize damage during transit.

The International Safe Transit Association (ISTA) outlines a specific set of drop tests for parcels based on their weight. Parcel that are securely packed should be able to withstand damages from free falls from the listed heights.

| Weight of the Package | Drop Height |

|---|---|

| 1 - 9.9kg | 75 cm above the ground |

| 10 - 19.9kg | 65 cm above the ground |

| 20 - 30kg | 45 cm above the ground |

Testing Method

Parcels should be let go (free fall) from the recommended height in accordance to their weight. Please do not throw the parcel.

The following five tests can be executed in any order:

- Free fall with parcel landing on its corners.

- Free fall with parcel landing on its flat base.

- Free fall with parcel landing on its flat top.

- Free fall with parcel landing on its longest side.

- Free fall with parcel landing on its shortest side.

After Drop Test

No functional and mechanical failures should be found on product and retail packaging after test.

Drop test consider fail if:

- The package is completely smashed/open.

- The product's retail box is badly damaged.

- The product inside is damaged or inoperative

Reminder

- Fill empty space completely.

- Multiple-parcel packaging and one-waybill for multiple-parcel are prohibited.

- Make sure the recycled material is in a clean, dry, and sturdy condition.

- A folded waybill is prohibited.

- Avoid using fabric/clothes-type materials for wrapping the parcel.

- Apply newspaper as filler to fill the empty space and save cost.

For further information and latest updates, do like and follow J&T Express Facebook page @J&T Express - Malaysia (https://www.facebook.com/jntexpressmalaysia/), Instagram at @jtexpress. You may also head on to our website at www.jtexpress.my or download our latest mobile application in Google Play Store and/or App Store by searching J&T Express Malaysia.

J&T Express - Express Your Online Business

Chat via Whatsapp

Chat via Whatsapp